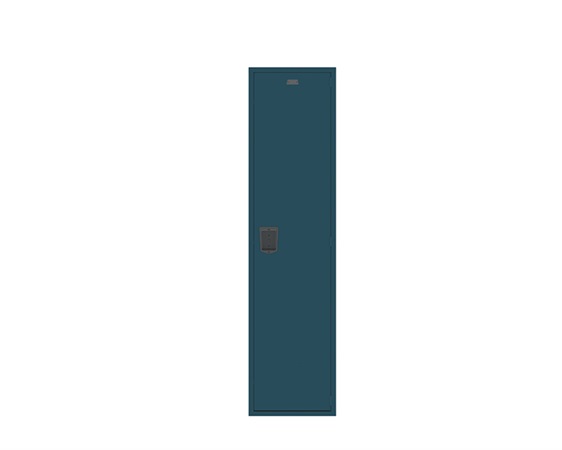

Guardian™ - Employee Lockers

Penco’s Guardian™ Lockers are perfect for offices and employee breakrooms. They build upon the design features of the Vanguard series with several enhancements and options that allow for a distinctive look. Our one-piece deep drawn Classic III™ stainless steel recessed pocket is part of every Guardian. It eliminates protrusions from the locker front and accepts a padlock or a built-in lock. The 16-gauge door front has a solid exterior, aiding quiet operation. Ventilation is provided by slots in the top and bottom flanges of the door.

Guardian’s Knocked Down Construction is designed with solid 16-gauge doors and Classic III Stainless Steel Recessed Handle. Diamond-shaped ventilation is also available with the Guardian Plus or Guardian Defiant II 14-gauge door.

Medallion Option

This upgrade has a sound damping panel welded to the door, reducing noise levels when doors are slammed.

Guardian PLUS

This upgrade increases the thickness of the door to 14-gauge. The Guardian PLUS locker is ideally suited for corridors and environments where the locker is likely to encounter harsher than normal usage.

Guardian Defiant II

This combines a 14-gauge door with a single point latch stainless steel pocket and a reinforcing pan that stiffens the door.

Half Height Locker 1 Tier

Available in 36-1/2" and 48-1/2" heights. Available with Classic III and Single Point Latch Defiant doors. Available in 12", 15", and 18" depths with a 12" width. Only 48-1/2" high lockers will include a shelf for storage of books and small articles.

| Color Number | Color Name | Color |

|---|---|---|

| 054 | Canvas | |

| 021 | Gray Ash | |

| 028 | Gray | |

| 073 | Champagne | |

| 723 | Light Putty | |

| 012 | Tawny Tan | |

| 701 | Spray Green | |

| 952 | Turquoise Teal | |

| 055 | Shamrock | |

| 812 | Hunter Green | |

| 715 | Lake Blue | |

| 826 | Slate Blue | |

| 806 | Marine Blue | |

| 052 | Reflex Blue | |

| 822 | Regal Blue | |

| 058 | Nordic Purple | |

| 056 | Sunburst | |

| 710 | Sagebrush Yellow | |

| 720 | Mandarin Orange | |

| 722 | Patriot Red | |

| 767 | Cardinal Red | |

| 736 | Burgundy | |

| 848 | January White | |

| 949 | Jet Black |

NOTE: Colors shown are as close to actual finishes as the printing process allows. Do not make your final color selection based on the color shade shown on this page. Penco Color Charts are available for a more accurate color match. Exposure to high humidity, chlorine salts, abrasive cleaners, germicidal cleaners and acids can damage the finish and will void the guarantee. For outdoor applications or other harsh environmental conditions, contact your Penco Representative.

View Our Configurator

Our configurator allows you to find a Penco product to meet your specific needs.

Start Now