Pallet Rack Plus – Seismic-Rated Pallet Racks

Pallet Rack Plus is engineered for use in areas where high seismic activity or other severe conditions exist. Load capacities are the same as the standard pallet rack, however the frames and beams are more resistant to horizontal and vertical forces that could damage the standard rack and its load.

Pallet Rack Plus beams have four connectors instead of three for a stronger connection between the beam and the upright post to resist conditions with higher lateral forces. The beam is welded 3” down from the top of the connector so loading is evenly distributed across all four connector prongs. The beam locking key is the same as used on standard beams. These seismic-rated pallet racks also come with

large footplates with extra holes provide the installer with more choices for floor anchoring.

Penco Pallet Rack Plus is engineered for use in areas where seismic activity or other severe conditions exist. To learn the seismic rating where your pallet rack will be in use, contact your Penco representative.

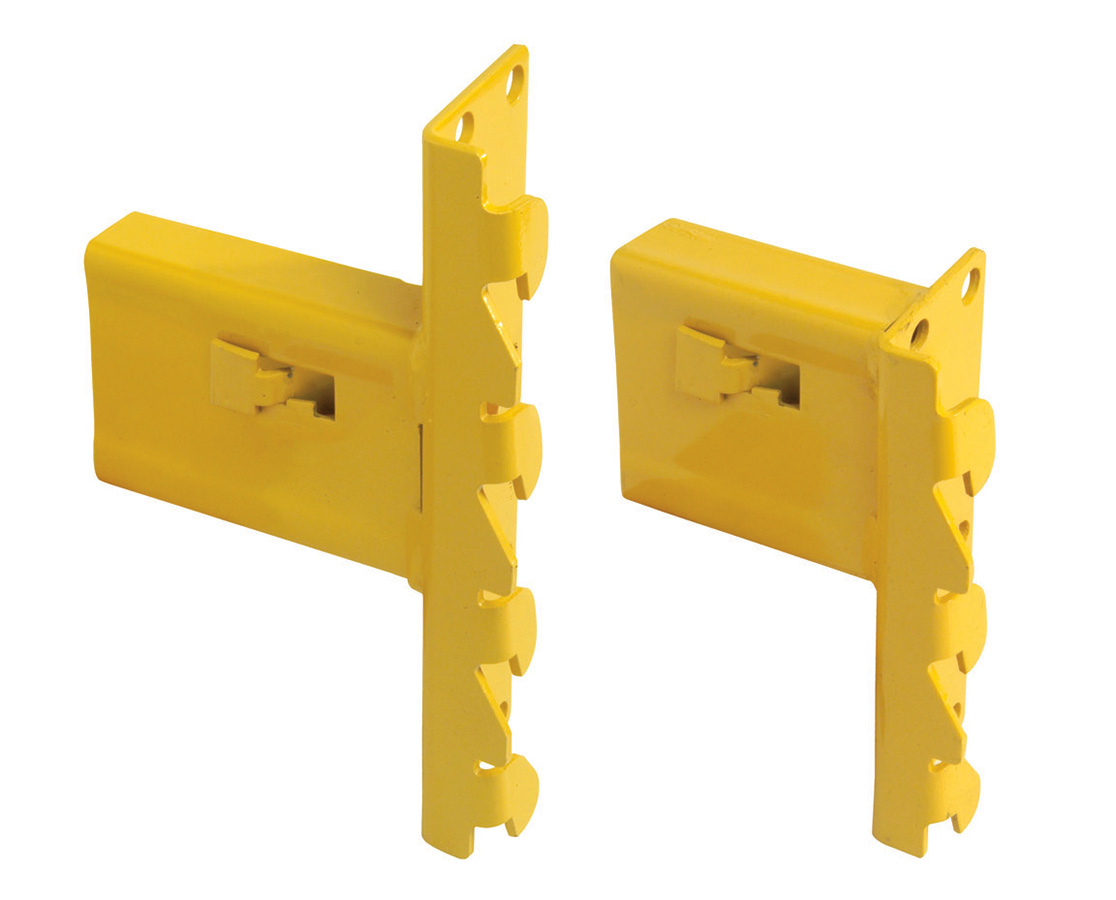

Plus Beam End Connectors

The Plus Beam End Connectors have four connector prongs instead of three. The beam is centered in the 11 ½” long connector so the load is distributed evenly across all four connector prongs. The beam locking key is the same as used on our standard beams. Penco end connectors are designed to slip into a slotted upright connection to create a compression fit. The more load placed on the beams, the tighter the connection becomes.

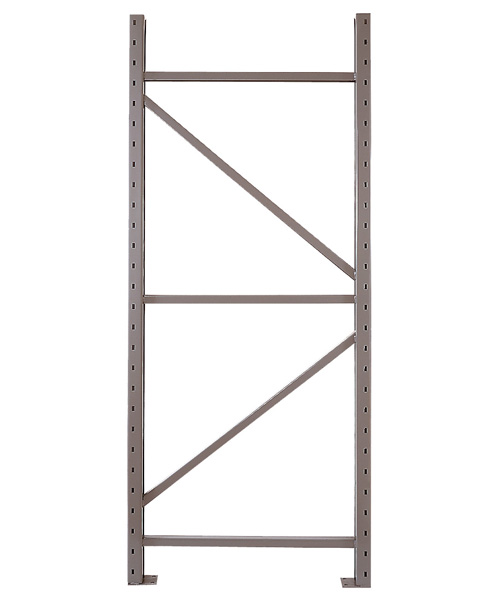

Plus Upright Frames with Large Footplates

Each Plus upright frame has two 5” x 7” x 3/8” thick footplates with four 9/16” diameter anchoring holes. The extra holes provide the installer with more choices for floor anchoring.

DESIGN FEATURES - PALLET RACK PLUS

The basic components of Penco Pallet Rack Plus are Upright Frames and Beams. Each is manufactured to exacting tolerances to provide many years of dependable service at their rated loads. Other components and accessories are available

STEP DOWN DESIGN: All beams have a step for the purpose of accepting accessories. Two step sizes are available: 7/8 " and 1-5/8" high.

BEAM LOCKING KEY FOR SAFETY: A unique recessed safety key installed into each beam connector that is made from heavy gauge steel engages a slot in the side of the post. As soon as beams are installed, the locking key should be slid into place. They will resist an upward force from material handling equipment up to 1000 pounds. It is an integral part of the beam assembly, can be engaged easily without tools, and is clearly visible for checking.

HEAVY DUTY BEAM END CONNECTOR: Pallet Rack Plus beams are intended for use in severe conditions or high seismic areas and have four pronged end frame connectors. The beams are centered along the 11 ½” long connector so all prongs share equally in the live beam load. Any Penco pallet rack beam can be equipped with four-pronged connectors.

WELDED UPRIGHT FRAME BRACING: Upright frame columns are securely MIG welded together with channel type braces for maximum rigidity.

UPRIGHT COLUMN: A continuous post roll formed into an "M" design for added strength. Slanted slots on the column allow for beam placement on 3" vertical centers. The greater the unit load the tighter the beam-upright connection becomes. All Plus pallet rack beams are attached 3” down from the top of the heavy duty connector and cannot be installed flush with the top of the uprights. Plus beams can be placed within 9” above the floor.

FOOT PLATE: All pallet rack Plus end frames have footplates that are 35 square inches and 3/8”thick. Four 9/16” holes are present at the corners for anchoring.

All Plus pallet rack uprights intended for severe or high seismic areas have footplates that are 35 square inches and 3/8” thick. Four holes 9/16” are present at the corners for anchoring.

PALLET RACK FRAMES

Penco Pallet Rack Plus Upright Frames are available in five different load carrying ranges. A letter code stamped into the face of the post indicates the frame type. Depths of 30", 36", 42", 48", 54" and 60" are standard, but other depths are available. Standard heights range from 48" to 240" in 6" increments, but greater heights can be achieved when upright frames are spliced together. Double posted and Cantilever leg custom upright configurations are available upon request.

Beam heights adjust on 3" vertical centers, and are independent on each side of the frame. Various load rated frames can be combined in a row of rack for maximum economy. Beams cannot be placed at locations where a splice is positioned.

Penco Pallet Rack Upright Frames are furnished completely fabricated, welded into rigid units. Standard finish for upright frames is 028 Gray baked enamel. Other standard Penco colors are available upon request.

We recommend that all upright frames be securely anchored to the floor. Seismic conditions and local codes may require anchors other than the Penco ½”-13 x 3 ¾” wedge anchor be used. We suggest you check with local code officials about anchoring as many jurisdictions have approved different anchors.

PALLET RACK BEAMS

Penco has engineered its roll-formed one piece beam to achieve the highest possible strength-to-weight ratios in the most frequently desired load ratings through the use of efficient design and high strength steel.

Beams are offered in eight basic styles with different vertical profiles and steel gauges. Beam step heights of 7/8" and 1-5/8" are available for a wide variety of accessory use. Both the overlapping seam and the beam end connector are securely MIG welded for strength.

The face of the beam has an M-design recessed configuration for added strength, protecting the locking key, and to accept pressure sensitive labeling. Each beam is stamped with an identifying letter referring to the load bearing capacity. Beams are finished in 710 Sagebrush Yellow baked enamel for high visibility. Safety Yellow and any other standard Penco colors are available upon request.

PALLET RACK ACCESSORIES

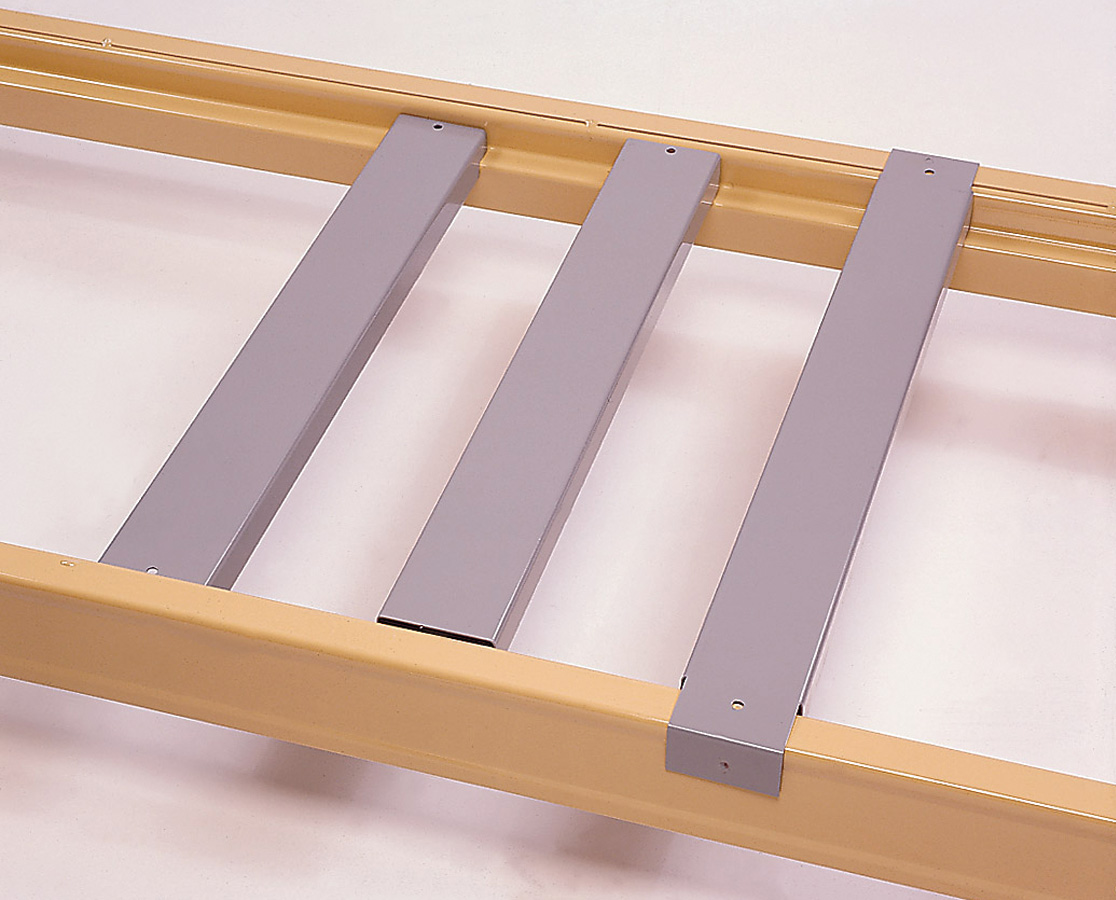

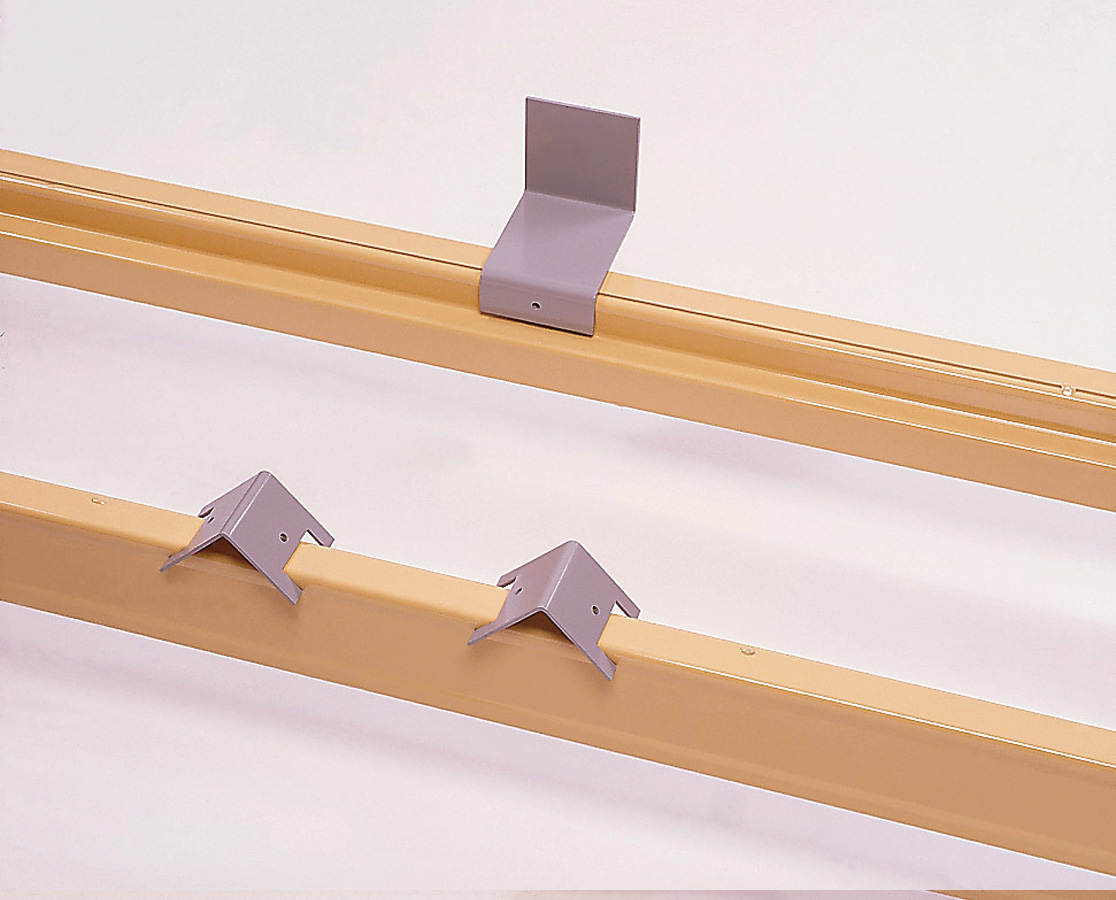

PLYWOOD SUPPORTS: For supporting plywood or other wood decking. Styles are available for 1/2" deck on 7/8" step beams and 3/4" deck on 1-5/8" step beams.

GENERAL DUTY CROSS BARS: For supporting loads smaller than unit depth.

HEAVY DUTY FLANGED CROSS BAR: Supports heavier loads smaller than upright end frame depth. Only available for use with 1-5/8" step beams.

FORK CLEARANCE BAR: Provides proper fork clearance for loads not on pallets. Fork clearance bars are 2 " wide by 2-3/4" high.

HEAVY DUTY SKID CHANNEL ASSEMBLY: Provides a channeled base for skid runners, 4" wide by 2" high.

FRAME SPLICE: For adding to height of existing frame. Can be supplied welded in top of new frame if specified on order. (Top frame must be ordered without foot plate.) With hardware. Can be used with standard or Plus uprights. Length of splice allows for two bolt locations on each side of the splice joint. Hardware for attachment is included. Top frames must be ordered without footplates.

FRAME PROTECTOR: Anchors to floor at front of post. Provides protection against damage from material handling vehicles.

FRAME DEFLECTOR: Fastens to front upright post on 3” increments.

RIGID WALL BRACKET: Structurally connects racks to wall for additional stability. Frame hardware included.

RIGID ROW SPACER: Structurally connects and spaces two rows of rack back-to-back to satisfy NFPA requirements. Bolted type. Hardware included.

REEL HOLDER: Accessorizes pallet rack for elevated reel storage. Capacity is 1,000 lbs/pair and they can hold axles up to 21/2” diameter. Hardware is included.

DECKING: Decking for pallet rack is available in a number of formats that include wire, steel and wood.

| Color Number | Color Name | Color |

|---|---|---|

| 054 | Canvas | |

| 021 | Gray Ash | |

| 028 | Gray | |

| 073 | Champagne | |

| 723 | Light Putty | |

| 012 | Tawny Tan | |

| 701 | Spray Green | |

| 952 | Turquoise Teal | |

| 055 | Shamrock | |

| 812 | Hunter Green | |

| 715 | Lake Blue | |

| 823 | Slate Blue | |

| 806 | Marine Blue | |

| 052 | Reflex Blue | |

| 822 | Regal Blue | |

| 058 | Nordic Purple | |

| 056 | Sunburst | |

| 710 | Sagebrush Yellow | |

| 720 | Mandarin Orange | |

| 722 | Patriot Red | |

| 767 | Cardinal Red | |

| 736 | Burgundy | |

| 848 | January White | |

| 949 | Jet Black |

NOTE: Colors shown are as close to actual finishes as the printing process allows. Do not make your final color selection based on the color shade shown on this page. Penco Color Charts are available for a more accurate color match. Exposure to high humidity, chlorine salts, abrasive cleaners, germicidal cleaners and acids can damage the finish and will void the guarantee. For outdoor applications or other harsh environmental conditions, contact your Penco Representative.